For a cognac producer "a tun" is not just a word. Cause in the depths

of an oak vessel happens the mysterious maturation of this drink that

cannot be seen with human eyes. The grape spirit filled in a tun absorbs old energy of the wood, its aromas and inevitably changes its color.

And the longer the spirit remains in the tun the richer and more diverse

the aroma of the cognac is.

This process of transformation of pure grape spirit in the dark amber

yellow liquid is truly magical. The taste of the spirit changes in so

many ways and you may feel flowers and muscat, coffee and vanilla, fruit

and chocolate. This very magic of transformation gives us the bouquet

of aromas and long changing aftertaste of the cognac for which it is so

highly valued and loved.

The procedures and technologies of cognac production are strictly

regulated. Oak for tuns should grow on the territory of France. Here

they use oak from two French regions: Limousin and Troncais.

And now we are going to see the production process of an oak tun for cognac at the largest coopering - Seguin Moreau plant.

Oak stems cut like sandwiches should dry out for 8 months in natural conditions.

Then they are sawn into planks that will form the future tun. They

should also dry out for 3-4 months more. The surface of the wood

blackens.

According to the drying technology they are sometimes watered.

Tasting oak juice

All wooden pieces are strictly sorted, marked and checked for defects.

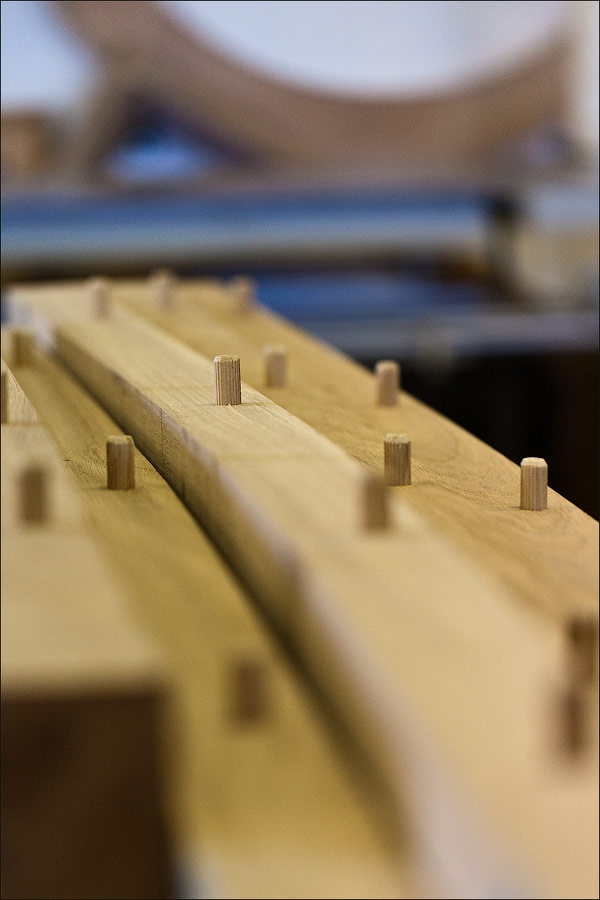

After drying the workpieces are planed and making process begins. Firstly, one side of the tun is fixed on the metal hoop.

Half-tun is placed onto the fire basket for burning of the inside. Fire

makes the oak surface softer and as a result of heating the glucose

contained in the wood appears the sugar coating.

Extent of burning also impacts the taste of the cognac.

The lower part of the tun is hooped.

The tun is turned upside down and burnt again.

And finally tightly fixed with hoops.

Polished

Bottoms are fixed

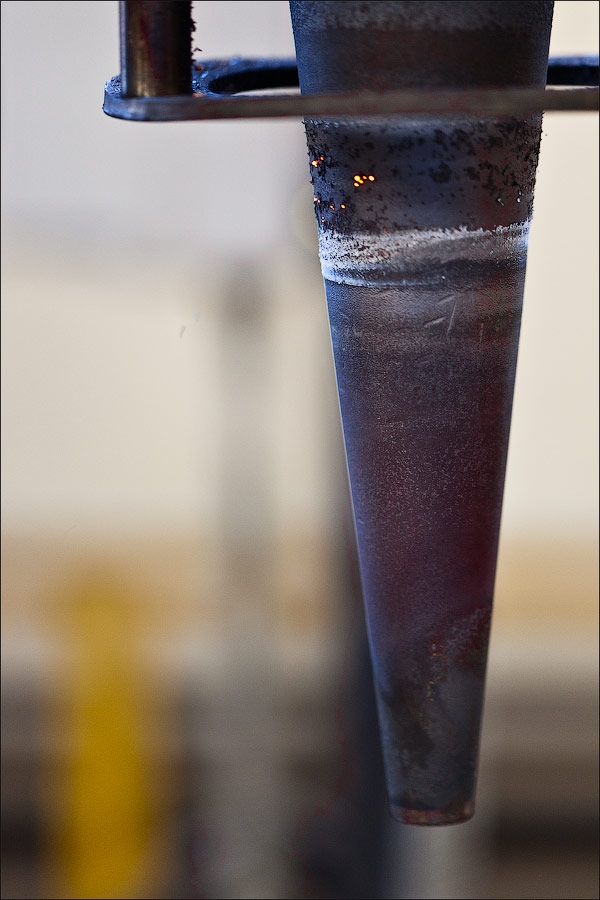

With a boiling hot "sting" the filler hole is burnt through.

It has a conic form and a standard size.

The tun is completed with a cork.

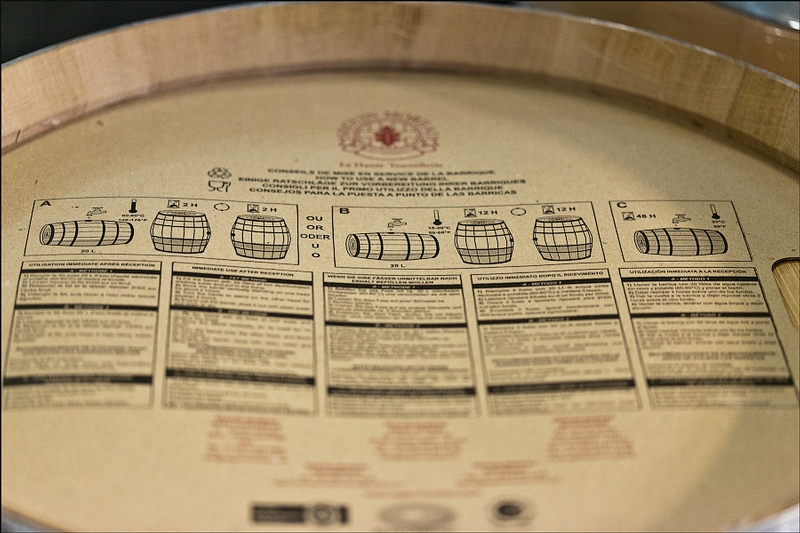

Instructions

Pride label

And the tun goes to the warehouse of ready products.

In a separate workshop tuns for wine are made.

via kukuksumushu

0 comments:

Post a Comment